END SUCTION PUMPS

Type LF (Frame Mounted)

Type LC (Close Coupled)

Type LCV (Vertically Mounted Close Coupled)

Grundfos CBS Inc. is fully committed to advancing pump technology and providing its customers with the most efficient pumps in the market.

The PACO line of end suction, single stage pumps serves as the industry standard in performance, quality, and durability. With an expanded selection of 32 sizes available, the PACO line of pumps are the smart choice for a number of reasons:

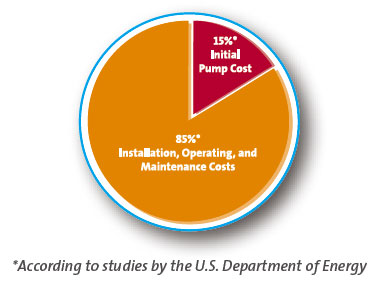

- Low life-cycle costs

- High efficiency for reduced operation costs

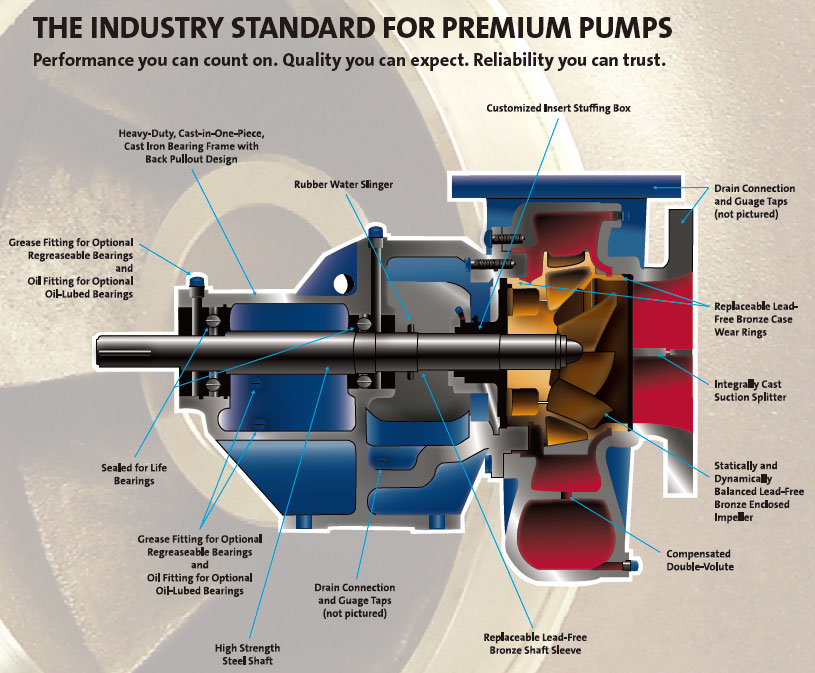

- Compensated double-volute design for reduced radial loads, minimized shaft deflection, and prolonged seal life and bearing life

- Mechanical design for reduced maintenance and minimal downtime

- Back pull out design for ease of maintenance and servicing

- Range of sizes to meet precise application requirements

- Quiet operation

Advanced features incorporated as standard on PACO end suction pumps ensure optimum performance and reliability. These features, as well as optional features that meet specialized needs, are available on the broadest line of high-efficiency pumps offered to the industry.

An innovative pump and impeller design produces a higher operating efficiency – up to 91 percent – and provides a wider band of best operating efficiency, even during conditions of off-design operation.

Quite simply, the PACO line of pumps is the smart choice for lower initial cost, longer pump life, reduced operating and maintenance costs, maximum reliability, and quieter operation.

LF/LC/LCV

Double Volute Design with

Superior Advantages

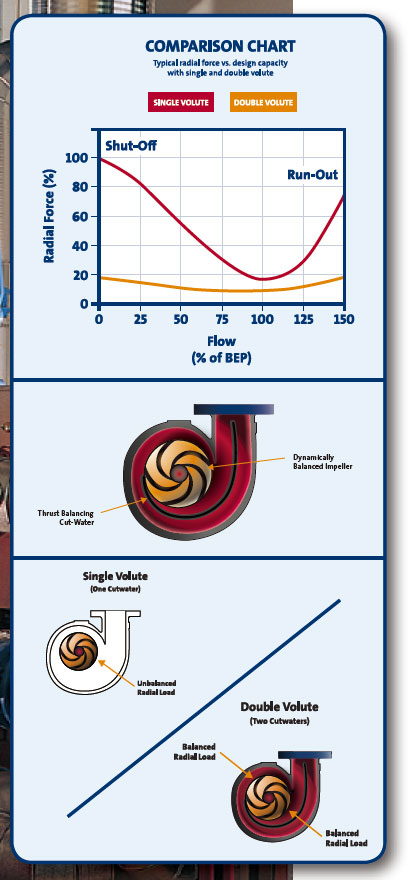

The PACO LF and LC pumps utilize a double volute design that offers a distinct advantage over single volute designs. The double volute design incorporates two cutwaters located at 180°, which divide the flow into two geometrically similar regions of the volute.

The resultant hydraulic forces within the pumps are equal and opposed. As a result, the net radial force is maintained at a very low level throughout the operating range of the pump, and shaft deflection is kept to a minimum.

A typical single volute pump is normally designed to operate at or near the best efficiency point (BEP).

In actual application, many pumps stray away from BEP due to load variances and/or changes in

the system head curve.

As single volute pumps begin to operate away from BEP, the resultant radial load increases dramatically, causing increased shaft loads, deflection, and vibration. Excessive radial loads can

cause premature failure of the mechanical seal, bearings, and shaft.

A double volute design ensures that hydraulic radial loads are equal and opposed and thereby nullified.

Pump operation remains stable throughout the entire performance curve, with minimal shaft deflection, prolonging seal, bearing, and shaft life.

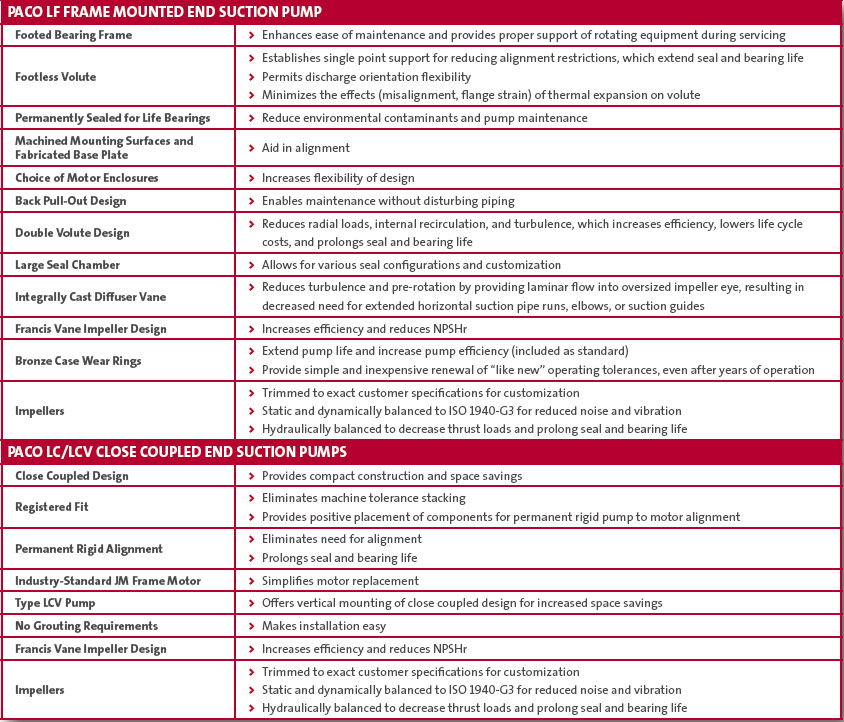

FEATURES AND BENEFITS

LF/LC/LCV

End Suction Pumps

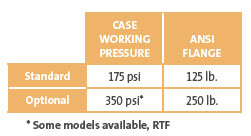

Technical Data

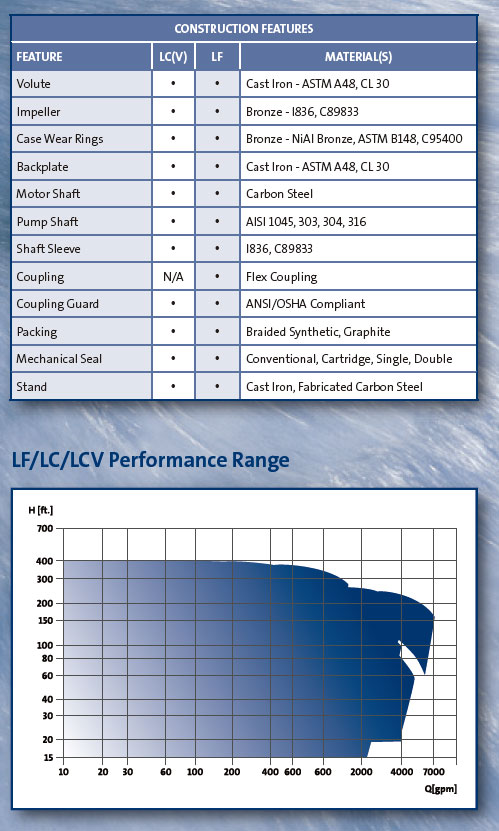

Flow, Q: max 6,000 gpm

Head, H: max 400 feet

Fluid temp.: max 275° F

HP range: 1/3 to 300 hp

Discharge sizes: 1” to 10”

Applications

• HVAC

• Plumbing

• Industrial

• Wastewater

Standard Features

• Lead-free bronze construction

• Dynamically balanced enclosed-type impellers

• Mechanical seal or packed box

• Suction and discharge pressure gauge taps

• Full-flanged connections on discharges 2-1/2” and larger

• Internal case suction splitter

• Low NPSH requirements

• Wear rings

• Rigid designed steel base with machined pump and motor mounting surfaces

Optional Features

• Materials of construction

• Alloy shafts and sleeves

• Seal materials and configurations

• Motor enclosures (TEFC or explosionproof)

Certifications

• ISO 9001 Certified

• ANSI/NSF-50 Standard Certified available

• ANSI/NSF-61 Standard Certified available