EXPERIENCE WHERE IT COUNTS

Nothing speaks volumes more than the expertise of a company and their ability to continually provide high-quality, reliable products. With more than 60 years of experience in the design, manufacture, and application of pumps and pumping systems, you can rest assured that a Grundfos pump is a sound investment.

Grundfos is a pioneer of innovative pumping solutions and dedicated to developing, producing, and selling the highest quality pumps and pumping systems while at the same time contributing to a better quality of life and a healthier environment.

With a focus on reliability, premium quality, high efficiency, low life-cycle costs, and sustainability, Grundfos has become the preferred partner and supplier for consulting engineers, municipalities, developers, and building owners.

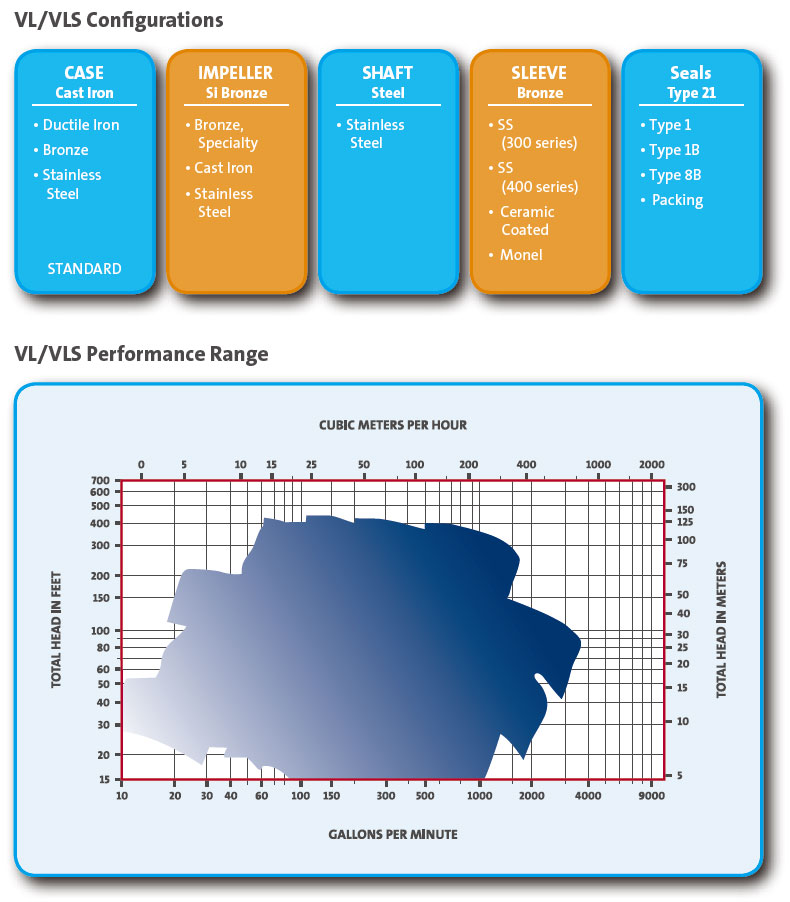

The PACO VL/VLS series of Grundfos pumps are part of the SMART family of pump products which are better engineered to increase efficiency and reduce radial loads. SMART pumps are also designed to help reduce operating and maintenance costs.

The VL/VLS Inline pumps have proven to be extremely versatile, often exceeding the requirements for a variety of market applications, such as chilled water, condenser water, and hot water systems.

WHAT’S YOUR

INSTALLATION

FOOTPRINT?

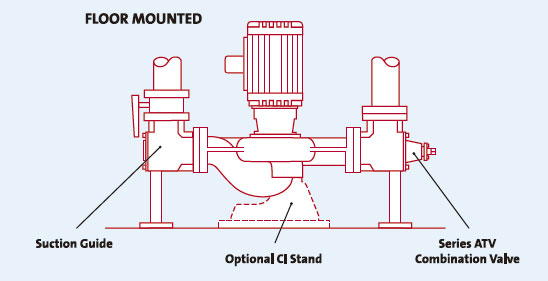

When floor space is a consideration, you’ll want to go with the VL. Where many other pumps might not fit, the VL’s vertical inline mounting guarantees the smallest footprint, literally requiring no floor space.

INNOVATIVE DESIGN FOR

OPTIMUM OPERATION

Grundfos pushes the limits of pump performance. The VL offers comprehensive sizes and configurations to meet your needs. It has a superior hydraulic and mechanical design, which produces higher efficiency, reduced pump noise, and longer pump life.

The VL can be fitted with a speed-control system, which significantly cuts energy use and provides a pump payback in as little as one to two years.

Now that’s a benefit you can take to the bank!

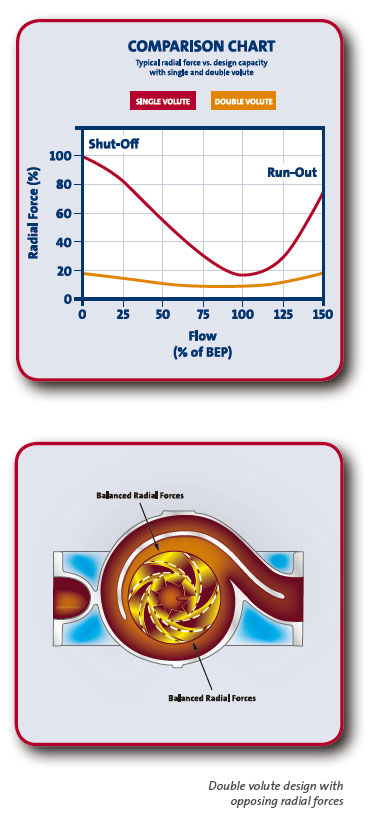

THE DOUBLE VOLUTE

DESIGN DECIPHERED

The compensated double volute is another design feature that differentiates a Grundfos pump from the rest of the pack. The double volute design virtually eliminates radial forces caused by a hydraulic imbalance inherent in pump volutes.

Here’s what’s happening: the double volute creates a secondary cutwater 180 degrees offset from the volute cutwater that is formed where the discharge and impeller meet. This creates equal forces acting upon the impeller. Another outcome is extended seal and bearing life, which minimizes vibration and noise.

The double volute design improves efficiencies by providing two individual passageways to guide flow in the casing, creating a more stable flow and a broadband efficiency range. The roadband efficiency keeps efficiency losses to a minimum as flows move away from the best efficiency point (BEP).

One other feature of the volutes is a back pullout design, which allows for easy removal of the pumps rotating assembly without disturbing the piping connections.

FEATURES WITH BENEFITS

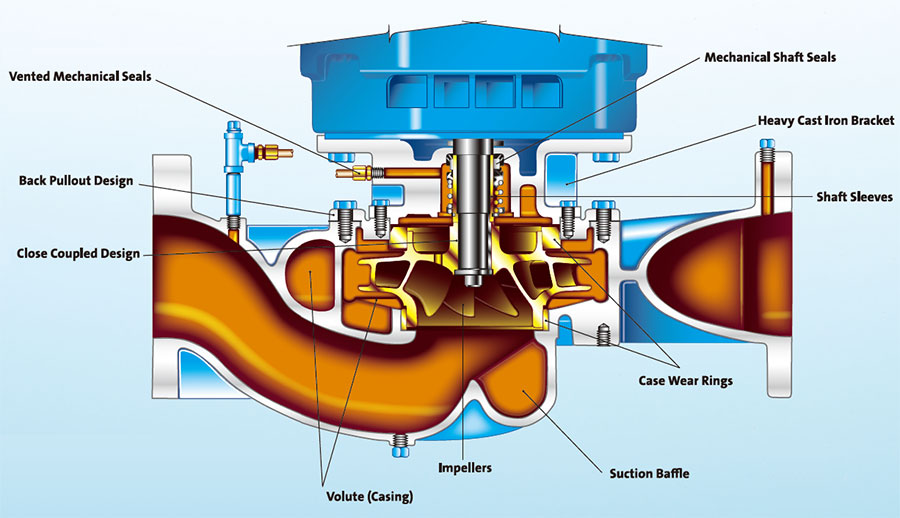

BRACKETS

- The heavy duty cast and machined motor bracket provide the motor with a rigid and reliable mounting surface

- Accurately machined register fit of brackets allows for concentricity and near perfect alignment of rating parts

CASE WEAR RINGS

- Replaceable case wear rings protect the pump casing from wear and tear and permit simple and easy maintenance of proper running clearances

- Case wear rings reduce maintenance costs and help maintain high operating efficiencies

INLINE FLANGES

- Inline design allows for space savings, being mounted “in-the-line” requiring no floor space

- Inline design reduces initial cost by saving in material and installation costs with bases and mounting foundations

- Flanges are sized with the same suction and discharge sizes according to flow rate to most engineered pipe sizing, thus eliminating the need for reducers, elbows, or other fittings

IMPELLERS

- Engineered “closed” (double shrouded) impellers with Francis Vane design improves the pump’s efficiency

- Extended vanes and enlarged eye contribute to a reduction in vibration and noise as well as reduced overall NPSH required for these pumps

- Impellers are statically and dynamically balanced to ISO 1940-G3, decreasing noise and vibration

- Hydraulically balanced impellers reduce radial loads, prolonging seal and bearing life

- Multiple material selections allow for customized solutions to meet specific application requirements

SHAFT and SHAFT SLEEVES

- Vertical configuration of the shaft eliminates shaft slope and related distortions, promoting longer seal and bearing life compared to conventional horizontally mounted units

- Shaft sleeves are available in a wide variety of metallurgies, such as steel, bronze, etc.

- Sleeve protects the shaft from corrosion and wear, extending the overall life of the shaft and usable life of the pump

SUCTION BAFFLE

- Integrally cast suction baffle directs flow directly into the eye of the impeller for a more even istribution flow, eliminating pre-rotation and suction losses and creating a smooth, quiet pump operation

VOLUTE

- Compensated double volute design virtually eliminates radial forces caused by a hydraulic imbalance inherent in pump volutes

- Double volute design extends seal and bearing life, minimizing noise and vibration, and improving operating efficiency

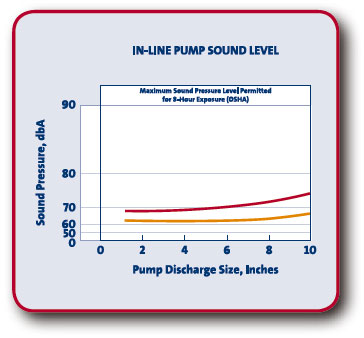

QUIETER OPERATION.

HIGHER EFFICIENCY.

Minimum pump noise is a necessity in most applications. Construction costs for modern commerical

buildings have led to a closer proximity of work areas to mechanical rooms.

Because fluid- or structure-borne noise problems are difficult and costly to solve, equipment that runs quietly has become essential in nearly every application.

To ensure building owners the least possible noise is generated by their pumps, maximum sound levels should clearly be specified in the same manner as capacity, head, and efficiency requirements.

The chart below illustrates sound level requirements and test procedures performed in accordance with the Hydraulic Institute’s standards for measuring sound produced by conventional pumping equipment.

A SMART PUMP

The VL Vertical Inline pump falls into the SMART family of products with superior hydraulic and mechanical design that produces higher operating efficiency, reliability, and reduced pump noise.

INSTALLATION FLEXIBILITY OFFERS

SUPERIOR ADVANTAGES

- Saves floor space and reduces piping

- No flexible connectors or foundation grouting

- Mounts like a valve for quick installation

- No coupling alignment or bearing frame assembly

- Equal size suction and discharge pipes

- Easier to maintain and smaller spare parts inventory

VL/VLS

Vertical Inline Pumps

Technical Data

Flow, Q: 10 to 4,000 gpm

Head, H: 10 to 420 feet

Fluid temperature: -20° to 275° F

Working pressure: max 300 psi

HP range: ½ to 125

Discharge sizes: 1.25” to 10”

Impellers: 7” to 15”

Applications

• Chilled water

• Condensed water

• Hot water

• Service water

• District cooling/heating systems

• Boiler/hydronic heating

• Air conditioning

• Cooling towers

Markets

• HVAC

• Recreation

• Plumbing

• Aquaculture

• General Industry/Power Plants

• Wastewater

Standard Features

• Short shaft design

• Same-size suction/discharge connections

• Compensated dual volute design (3” and larger)

• Back pull out

• Small installation footprint

• Low/reduced noise

Optional Features

• Various materials of construction

• Various seal materials and configurations

• Support stand

• High pressure capabilities

Certifications

• NSF 61/50 (available upon request)