PACO KP/KPV 양흡입펌프

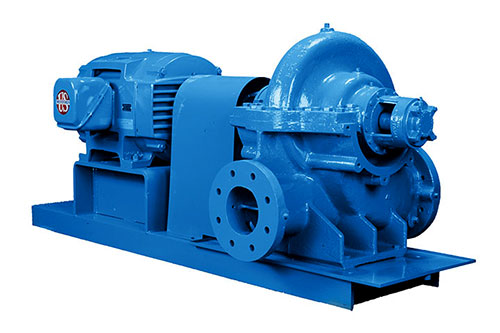

KP

Horizontally Mounted Split Case Pump

KPV

Vertically Mounted Split Case Pump – Sleeve Bearing

KP/KPV

Double Suction Split Case Pumps

Technical Data

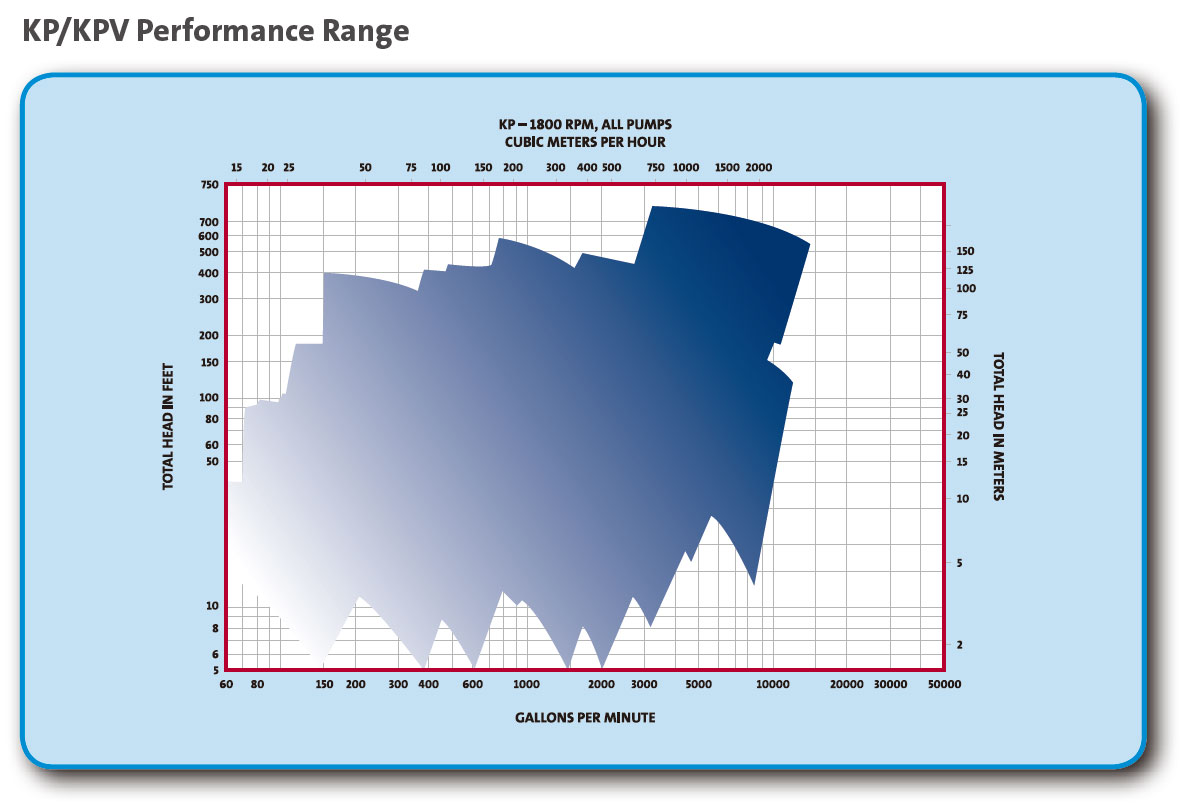

Maximum flow rate: 3,800 m3/h

Maximum head: 215 m

Fluid temperature: -20° to 275° F

Motor pole: 2, 4, 6

Motor frequency: 60 Hz

Suction diameter: 65-350 mm

Discharge diameter: 50-300 mm

KPV Sleeve Bearing

Fluid temperature: -20° to 150° F

Applications

• Chilled water

• Condensate water

• Commercial pools and water parks

• Direct and indirect cooling water

• Service water

• Water distribution systems

Markets

• HVAC

• Recreation

• Waterworks

• Irrigation/Agriculture

• General Industry (Steel Mills, Power Plants)

• OEM

Standard Features

• Wide hydraulic range

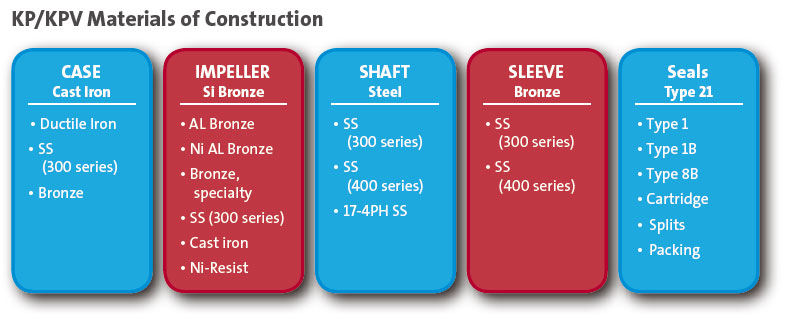

• Multiple material constructions and sealing arrangements

• Self-contained bearing housing

• Compensated dual volute design

• Vertical or horizontal mount for space savings

• Wear rings

• Sleeve bearing design

Optional Features

• Bearing lubrication option

• Impeller wear rings

• Various materials of construction

• Various seal materials and configurations, including cartridge (available in some models) and split seals

• NSF/ANSI-50 or NSF/ANSI-61 certifications (available upon request)

INNOVATIVE TECHNOLOGIES

The Grundfos philosophy is that only long-term savings are true savings, and PACO products are designed with this in mind.

The innovative hydraulic design, ease of maintenance, low life-cycle costs, and energy efficiency of PACO products assure maximum benefits for the user.

Grundfos understands custom applications and takes the customer’s desire for minimal installation and operating costs into account when developing products that significantly reduce the total cost of ownership over its lifetime.

KP/KPV pumps are reliable, field-tested, and can be configured to meet the specific requirements for a variety of commercial building applications.

HORIZONTAL SPLIT CASE – RELIABILITY BUILT IN

Grundfos’ humble, unstoppable workhorse – the KP – is always hard at work behind the scenes. KP double suction split case pumps are an engineer’s first choice for demanding applications where only the most reliable pumps go the distance.

The KP split-case design offers easy serviceability and better efficiency and operating performance compared to other designs. You get energy savings, lower life cycle costs, and peace of mind from day one.

The KP range features double volute construction, self-contained bearing housing, Francis Vane impeller design, and choice of application-specific materials of construction. Engineers have always favored KP pumps because of their reliability and quality.

With so many configurations possible, you can be sure to find the perfect solution with a customized KP pump.

The KP is designed to last. A few of the innovations which contributes to its solid performance include:

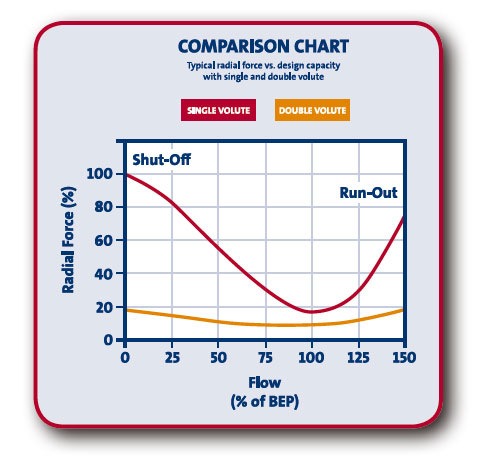

A compensated double volute balances radial loads reducing shaft deflection, which provides quiet operation and minimizes vibration, resulting in reduced maintenance cost.

Additionally, the double volute reduces turbulence and recirculation lost and improves efficiencies throughout the range, reducing operating cost.

The KP has a proven track record and is tested in accordance with current Hydraulic Institute standards, so you can count on its reliability before you purchase and put the pump to work.

A VERTICAL OPTION FOR SPACE SAVINGS

The KPV offers the same great design as the KP, but it is vertically mounted for a space-saving configuration.

The KPV features an accurately machined rabbet fit and locating pins, which permanently align the vertically mounted motor and pump, thus removing the need for alignment. The lower bearing on KPV mechanical seal type is designed with a protective moisture seal and water slinger to reduce the possibility of bearing damage caused by leakage from the pump.

The KPV with product lubed journal bearing in the bottom is very compact in the design. It eliminates the need for a lower mechanical seal and replaces a radial ball bearing with a journal bearing.

FEATURES AND BENEFITS

What makes the KP/KPV pumps so special? Let’s take a closer look at the innovative designs and technologies of the pump.

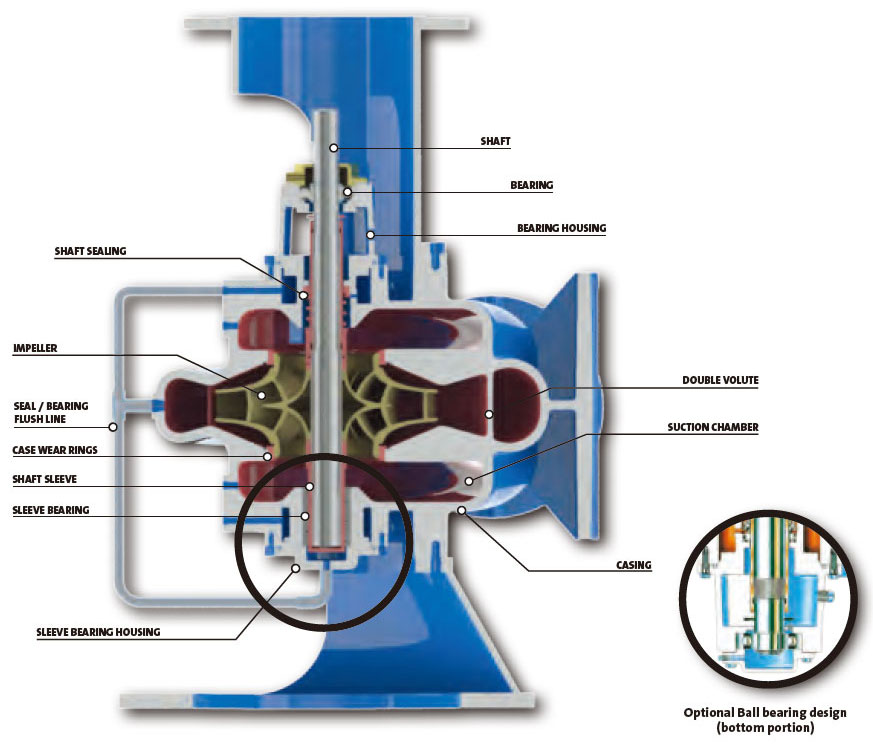

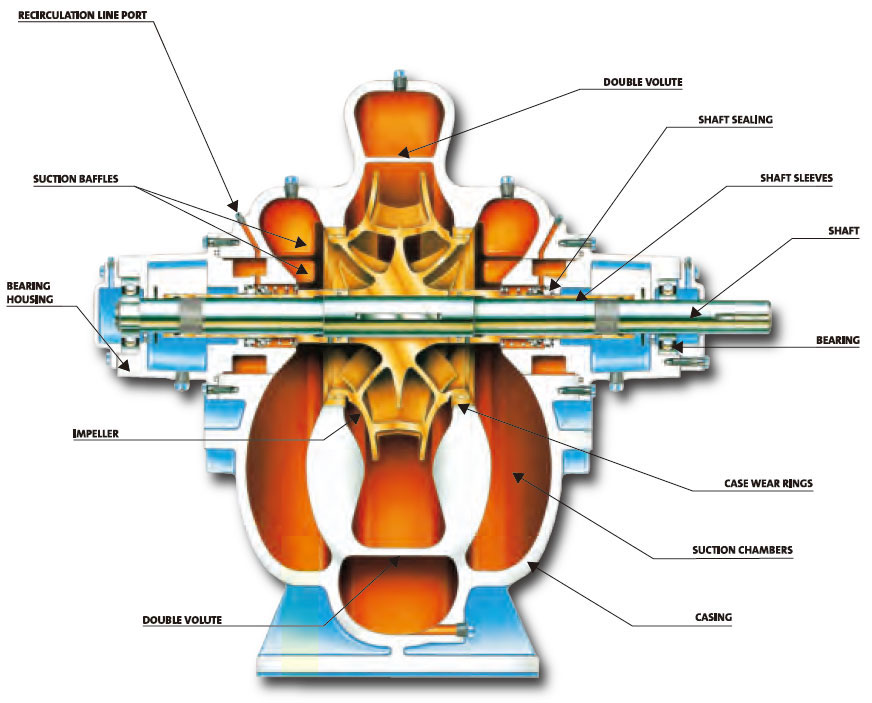

BEARINGS

- Selected in conjunction with short bearing span and large diameter shaft to provide a long life (minimum life of 10 years when calculated at 50% of BEP)

SLEEVE BEARING

- Spiral grooves flush contaminates and particles with recirculation line to reduce maintenance cost

SLEEVE BEARING HOUSING

- Compact, robust construction has 360-degree machined register fit to simplify removal and extend life

BEARING HOUSING

- Unique design combines seal and bearing chambers for ease of maintenance

- Allows for seal, sleeve, and bearing inspection without removing the top half of the casing

- Compact, robust construction with 360-degree machined register fit limits shaft deflection and optimizes alignment

CASE WEAR RINGS

- Replaceable case wear rings protect pump casing from wear and tear and permit simple maintenance of proper running clearances, reducing maintenance costs and helping to maintain high operating efficiencies

CASING

- Suction and discharge flanges are integrally cast into the lower casing half, allowing removal of the rotating assembly without disturbing the piping

- KPV is supported at its base to minimize vibration and extend pump life

IMPELLERS

- “Closed” (double-shrouded) with Francis Vane design improves pump efficiency

- Extended vanes and enlarged eye help reduce vibration and noise as well as overall NPSH required

- Statically and dynamically-balanced to ISO 1940- Grade G•3, decreasing noise and vibration

- Hydraulically-balanced, reducing loads, prolonging seal and bearing life

- Multiple material selections allow for customized solutions to meet application requirements

RECIRCULATION

- Recirculation lines allow for external lubrication or abrasive separation when required

SHAFT and SHAFT SLEEVES

- Large diameter precision-ground shaft minimizes shaft deflection and extends life

- Sleeve protects the shaft from corrosion and wear, extending shaft and pump life

SHAFT SEALING

- Pumps can be customized with any combination of mechanical seals or packaged configurations specifically selected to meet application requirements

SUCTION BAFFLES

- Integrally cast suction baffles direct flow from the suction into the eye of the impeller for a more even flow distribution, ensures less suction recirculation loss and promotes quiet, vibration-free operation as well as improving NPSHR

SUCTION CHAMBERS

- Inlet configuration increases hydraulic efficiency and lowers net positive suction head equirements

VOLUTE

- Compensated double volute design reduces radial forces caused by a hydraulic imbalance inherent in pump volutes

- Double volute design extends seal and bearing life, minimizes noise and vibration, and improves operating efficiency

An Inside Look at the KP

Single Stage Double Suction Horizontal Split Case Pump

An Inside Look at the KPV

Single Stage Double Suction Vertical Split Case Pump