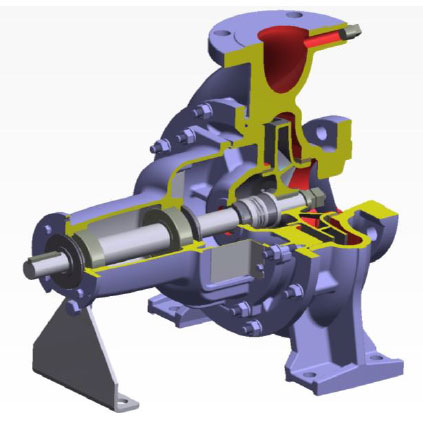

GS 편흡입 펌프

EBARA End Suction Volute Pump – Model GS

Applications

- Air conditioning-District heating & cooling

- Water supply duties for municipalities

- Irrigation

- Drainage clean water

- Fire protection

- Swimming pool

- Semiconductor Industry

- Food industry

- Pulp and Paper Industry

- Automobile industry

- Steel industry-Non-ferrous metals industry

- Garbage incineration

General Description

- Capacities : To 1,300 m3/hr (50Hz)

—————— To 1,500 m3/hr (60Hz) - Heads : To 150 m (50Hz)

————- To 150 m (60Hz) - Liquid temperatures : -10℃ to 140℃

- Max.working pressures : Up to 25Bar (2.5MPa)

- Materials : Casing : Cast Iron , Ductile Cast Iron

—————- Impeller : Cast Iron , Ductile Cast Iron , Bronze, Stainless Steel - Standards : EN733

- Rotation : Clockwise viewed from coupling end

SELECTION CHART

Note1 : The values inside the broken lines are motor output(kW) in case of density 1.0kg/ℓ and viscosity 1.0mPa・s.

Note2 : The indicated motor output(kW) value includes the following safety margins ;

up to 7.5kW : 15%

11kW and above : 10%

Note3 : When selecting a pump , NPSH Av. should have a safety margin of at least 0.5m from NPSH Re.

Product Features

Energy-saving Design

- World top class pump efficiency achieved.

- Major improvement over our previous models by impeller designed using our proprietary 3D inverse design technology.

- Higher efficiency means lower energy consumption and motor output, and more compact size.

Simple Maintenance

- Back pull-out structure enables disassembly and inspection without removal of suction and discharge piping.

- Shield bearings eliminate need for adding or exchanging lubricating oil.

- Shaft seal flushing and quenching piping not required for the standard application.

- Air-bleeding not required.

- Simplified bearings and shaft seal enable easy assembly.

Pump Specifications

- Maximum operating pressure: 25 bar

- Liquid temperature range expansion:-10℃ to 140℃

- Compatible with multiple flange standards.

- Able to meet customer specifications with many combinations of shaft seals and materials.

International Standards

- Pump dimensions adopt EN733

- Mechanical seal adopts EN12756

- Protector fitted in accordance with EN294.