DESMI ROTAN GEAR PUMP ED

ED Materials : Cast iron, carbon steel or stainless steel

- Capacity range : Up to 90 m3/h

- Speed : Up to 1750rpm

- Differential pressure : Up to 16bar

- Suction lift : Up to 0.5bar vacuum while primming

Up to 0.8bar vacuum while pumping - Viscosity rang : Up to 10,000 cSt

- Temperature : Up to 250℃

ED is for Environmental Duty. As only minimal maintenance is necessary, ED pumps will be a very economical solution compared with traditionally sealed pumps, especially where the application requires the use of double mechanical shaft seals. Often these applications are very arduous resulting in the seals and support system requiring regular attention and/or replacement. Thus, the life cycle costs for ED pumps are generally much lower than for pumps using two seals.

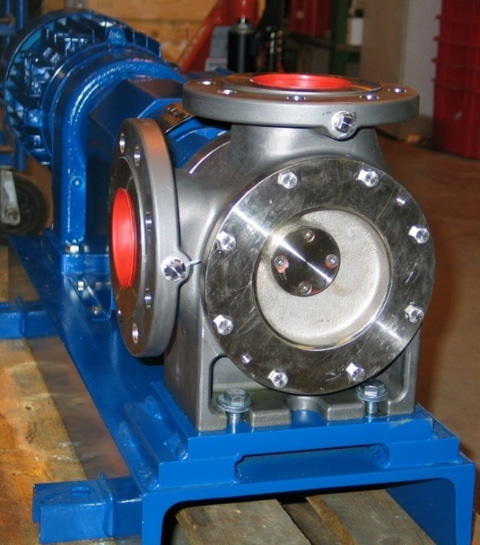

Mag Drive pump with right angle outlet port

Mag Drive pump coupled with integrated frequency converter

Key features and benefits

• Reversible direction of flow with double acting relief valve option available

• Coupled direct to NEMA or IEC motor for speed up to 1750 rpm

• Directed coupled gearbox with NEMA or IEC electric motor eliminating alignment issues

• Adjustable rotor end clearance without opening the system to the atmosphere

• Torque capabilities in excessive of 800 ft-lb

• Flow rates max. 90 m3/h with differential pressure up to max. 16 bar.

• Iron, Steel and Stainless Steel construction

• Tungsten Carbide abrasive wear materials are available for abrasive duty applications

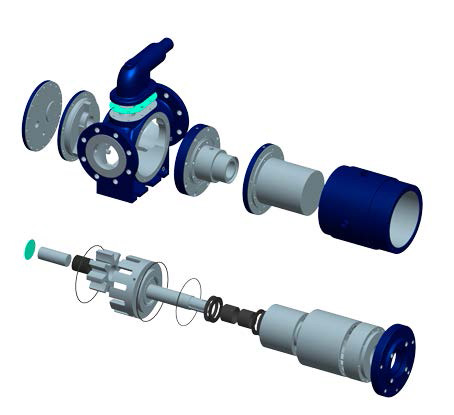

Magnetically coupled pumps for ultimate protection against leakage.

As only minimal maintenance is necessary, ED pumps will be a very economical solution compared with traditionally sealed pumps, especially where the application requires the use of double mechanical shaft seals.

Often these applications are very different, resulting in the seals and support system requiring regular attention and/or replacement.

Thus, the life cycle costs for ED pumps are generally much lower than for pumps using two seals.

Available with 90° angular configuration.

- Materials : Cast iron, carbon steel or stainless steel

- Capacity Rangee : Up to 90 m3/h / 396 gpm

- Speed : Up to 1750 rpm

- Differential Pressure : Up to 16 bar / 232 psi

- Suction Lift : Up to 0,5 bar / 7.25 psi vacuum while priming

————— Up to 0,8 bar / 11.6 psi vacuum while pumping - Viscosity Range : Up to 10,000 cSt

- Temperature : Up to 250°C / 482°F

- Common Applications : Where no leakage, liquid or gaseous, is allowed.

- Pumping of : Isocyanate, Solvents, Hazardous organic liquids, Printing ink, Resin, Pitch, Alkyd resin, Soyabean oil, Linseed oil, Monomers, Polyol, Corn syrup

PLEASE NOTE!

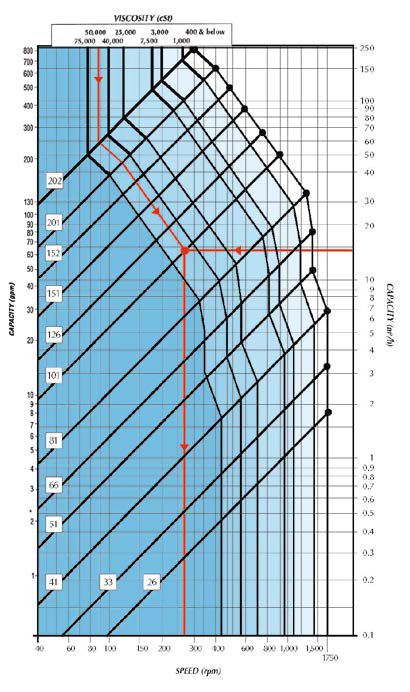

ED: Capacity curve up to 151

GP: Capacity curve up to 101

To select the pump size with this table, you should only know:

– The capacity

– The viscosity

We start at the top of the table with the viscosity, and draw a line down, staying within the colour of the selected viscosity range (see example).

Then we start at the right of the table, drawing a horizontal line starting with the required capacity (see example).

The point where these two lines meet determines the pump size, defined by the diagonal lines in the table. If you do not hit one of these pump lines exactly, increase the capacity a bit. The speed is found vertically below the point of intersection (see example).

The maximum speed of each pump is found vertically below the end of each pump line (indicated with the small black dot).

This maximum speed must be reduced to max. 50% when pumping strongly abrasive liquids or emulsions.

When the differential pressure is known, the shaft power is calculated by:

E(KW) = 0,07 x flow (m³/h) x differential pressure (bar)

The requested shaft power has to be increased by up to 35% when using a small ROTAN® pump in combination with high viscosity (Over 10,000 cSt).

The requested shaft power has to be decreased by up to 35% when using a big ROTAN® pump in combination with low viscosity (Under 500 cSt).