DESMI ROTAN GEAR PUMP GP

General Purpose pumps in cast iron,for clean, non-abrasive liquids

- Capacity range : Up to 50 m3/h

- Speed : Up to 1750rpm

- Differential pressure : Up to 16bar

- Suction lift : Up to 0.5bar vacuum while primming

Up to 0.8bar vacuum while pumping - Viscosity rang : Up to 7,500 cSt

- Temperature : Up to 150℃

Pumps of cast iron, for clean, non-abrasive liquids.

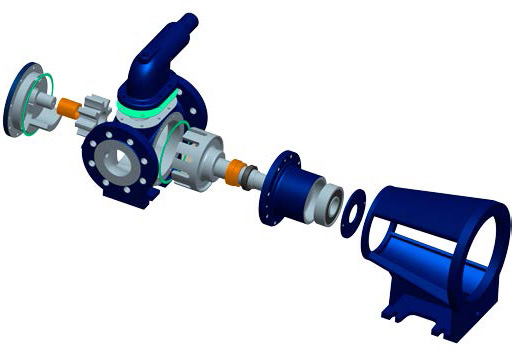

The simple and compact construction makes it a low-cost pump, often used in modified versions by OEM customers.

Applications – pumping of : Clean oil; Glycol; Vegetable oil; Solvents; Lube oil; Fuel Oil; Waste oil; Fish oil

Key features and benefits

• Flexible sealing options

• Opposing inlet and outlet connections with oversized ports

• Shaft supported by two ball bearings in single sealed configuration

• Self-priming with large suction capabilities

• Low NPSH requirements

• Self-draining, integral safety relief valve

• No speed reduction required in six smaller sizes

• Complete heating/cooling jacketing available

Pumps in cast iron, for clean, non-abrasive liquids.

The simple and compact construction makes it a low-cost pump, often used in modified versions by OEM customers.

A close-coupled OEM model is also available. GP pumps are designed for use with IEC or NEMA flange motors. Available with 90° angular configuration.

The DESMI ROTAN® pumps are used by all major oil product manufacturers around the world.

With a strong focus on the customers’ needs we aim to be the best application provider in the market.

We aim to develop new innovations in pump technology.

Therefore we cooperate closely with customers in order to solve individual application problems as well as develop new leading ideas for the industry.

We are always looking for ways of doing things better.

- Capacity Range : Up to 50 m3/h / 220 gpm

- Speed : Up to 1750 rpm

- Differential Pressure : Up to 16 bar / 232 psi

- Suction Lift : Up to 0,5 / 7.25 psi bar vacuum while priming

————— Up to 0,8 bar / 11.6 psi vacuumwhile pumping - Viscosity Range : Up to 7500 cSt

- Temperature : Up to 150°C / 302°F

- Pumping of : Clean oil, Glycol, Vegetable oil, Solvents, Lube oil, Waste oil, Fish oil

PLEASE NOTE!

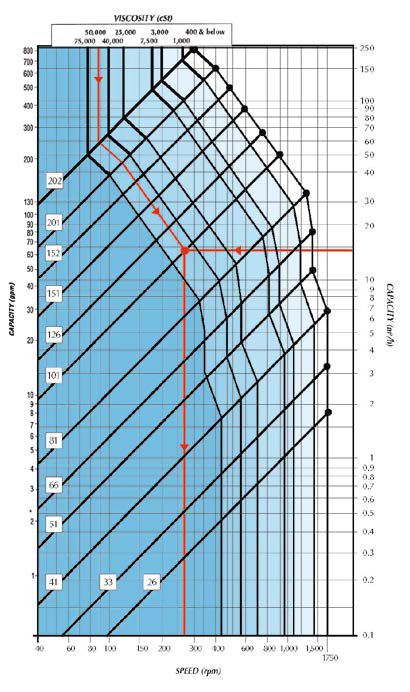

ED: Capacity curve up to 151

GP: Capacity curve up to 101

To select the pump size with this table, you should only know:

– The capacity

– The viscosity

We start at the top of the table with the viscosity, and draw a line down, staying within the colour of the selected viscosity range (see example).

Then we start at the right of the table, drawing a horizontal line starting with the required capacity (see example).

The point where these two lines meet determines the pump size, defined by the diagonal lines in the table. If you do not hit one of these pump lines exactly, increase the capacity a bit. The speed is found vertically below the point of intersection (see example).

The maximum speed of each pump is found vertically below the end of each pump line (indicated with the small black dot). This maximum speed must be reduced to max. 50% when pumping strongly abrasive liquids or emulsions.

When the differential pressure is known, the shaft power is calculated by:

E(KW) = 0,07 x flow (m³/h) x differential pressure (bar)

The requested shaft power has to be increased by up to 35% when using a small ROTAN® pump in combination with high viscosity (Over 10,000 cSt).

The requested shaft power has to be decreased by up to 35% when using a big ROTAN® pump in combination with low viscosity (Under 500 cSt).