DESMI ROTAN GEAR PUMP HD

Heavy duty pumps in cast iron, for a wide range fo vescous, non-corrosive liquids, designed for difficult application.

- Capacity range : Up to 170 m3/h (250CUMH)

- Speed : Up to 1750rpm

- Differential pressure : Up to 16bar

- Suction lift : Up to 0.5bar vacuum while primming

Up to 0.8bar vacuum while pumping - Viscosity rang : Up to 250,000 cSt

- Temperature : Up to 250℃

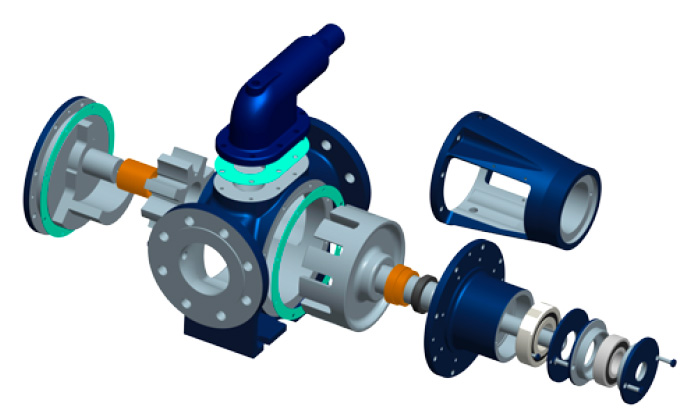

Pumps of cast iron, for a wide range of viscous, non-corrosive liquids. HD pumps are specifically designed for difficult applications and those involving high viscosity liquids.

Applications – pumping of : Oil; Asphalt; Chocolate; Paint; Lacquer; Molasses; Soap; Other industrial viscous liquids

Key features and benefits

• Flexible sealing options

• “True” back pull-out design

• Opposing inlet and outlet connections with oversized ports

• Shaft supported by two ball bearings in single sealed configuration

• Self-priming with large suction capabilities

• Low NPSH requirements

• Self-draining, integral safety relief valve

• No speed reduction required in six smaller sizes

• Complete heating/cooling jacketing available

Pumps in cast iron, for a wide range of viscous, non-corrosive liquids. HD pumps are specifically designed for difficult applications and those involving high viscosity liquids.

HD pumps are known by their sturdy and simple construction. Available with 90° angular configuration.

Production stops are the most costly activity in industry.

That is why companies all over the world rely on high quality pumps like DESMI ROTAN®.

- Capacity Range : Up to 250 m3/h / 1100 gpm

- Speed : Up to 1750 rpm

- Differential Pressure : Up to 16 bar / 232 psi

- Suction Lift : Up to 0,5 bar / 7.25 psi vacuum while priming

————— Up to 0,8 bar / 11.6 psi vacuum while pumping - Viscosity Range : Up to 250,000 cSt

- Temperature : Up to 250°C / 482°F

- Pumping of : Oil,Asphalt, Chocolate, Paint/Lacquer, Molasses, Soap, Additives, Polyol, Viscose, Sulphate soap, Maltose, Grease, Pitch, Base oil, Bitumen, Polyester