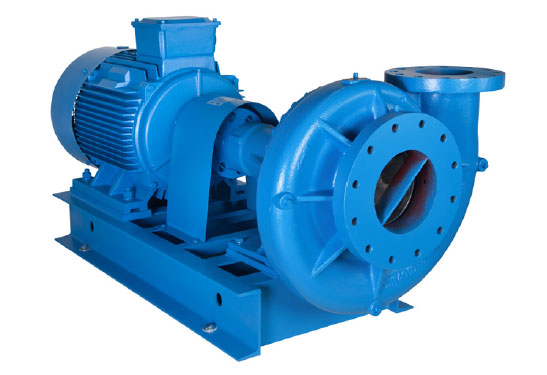

LF End Suction Pumps

PACO End Suction Pumps

Grundfos CBS Inc. is fully committed to advancing pump technology and providing its customers with the most efficient pumps in the market.

LF End Suction Pumps

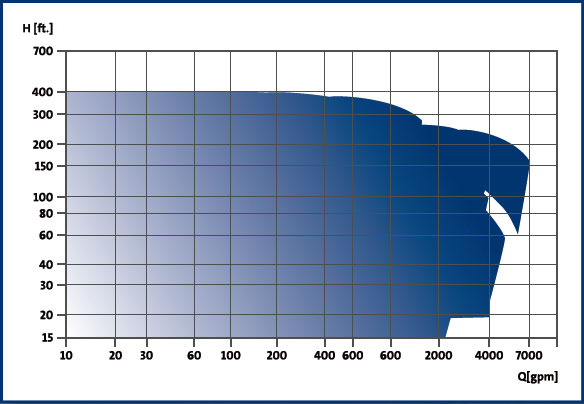

Performance range

• Capacity : 3 ~ 1,400 m3/h

• Head : 3 ~ 125 m

• Suction Dia : 40 ~ 300 mm

• Discharge Dia : 25 ~ 250 mm

• Efficiency : up to 90 %

• Motor Power : 0.3 ~ 315 kW

• Motor speed : 2, 4, 6 pole

• Frequency : 60 Hz

Applications

• Feed and drain water system

• HVAC system

• Firefighting system

• Domestic water supply system

• Others.

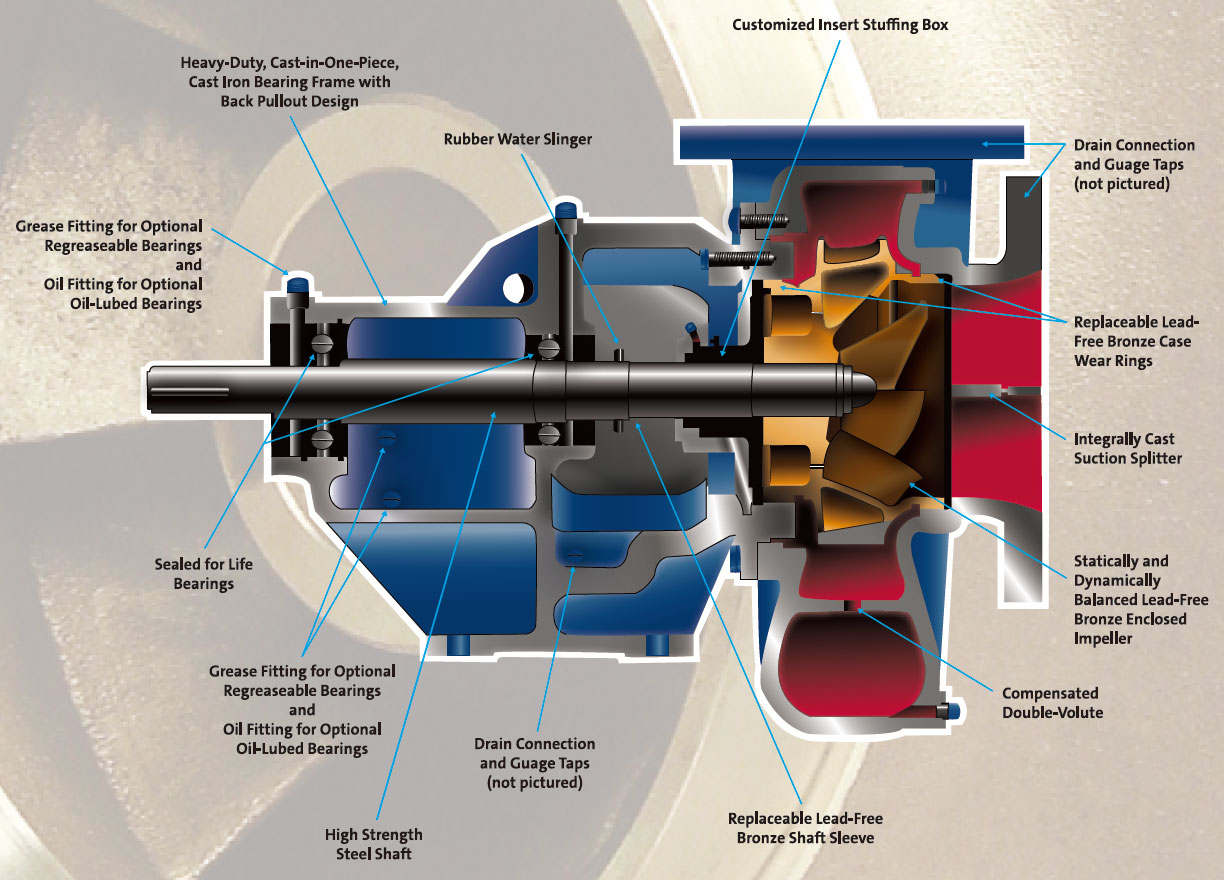

Standard pump features

• High efficiency-maintained over an extended operating range

• Double-volute casings on models with high specific speeds

• Dynamically balanced enclosed-type impellers

• Mechanical seal or packing seal

• Back pull-out design

• Integrally cast suction splitter on flanged models

• Low NPSH

Optional pump features include

• Ductile iron volute, Bronze impeller

• Special alloy shafts and sleeves

• Special mechanical seals

• TEFC or explosion-proof motors

• Abrasive separators

• Diesel engine drives

LF/LC/LCV Performance Range

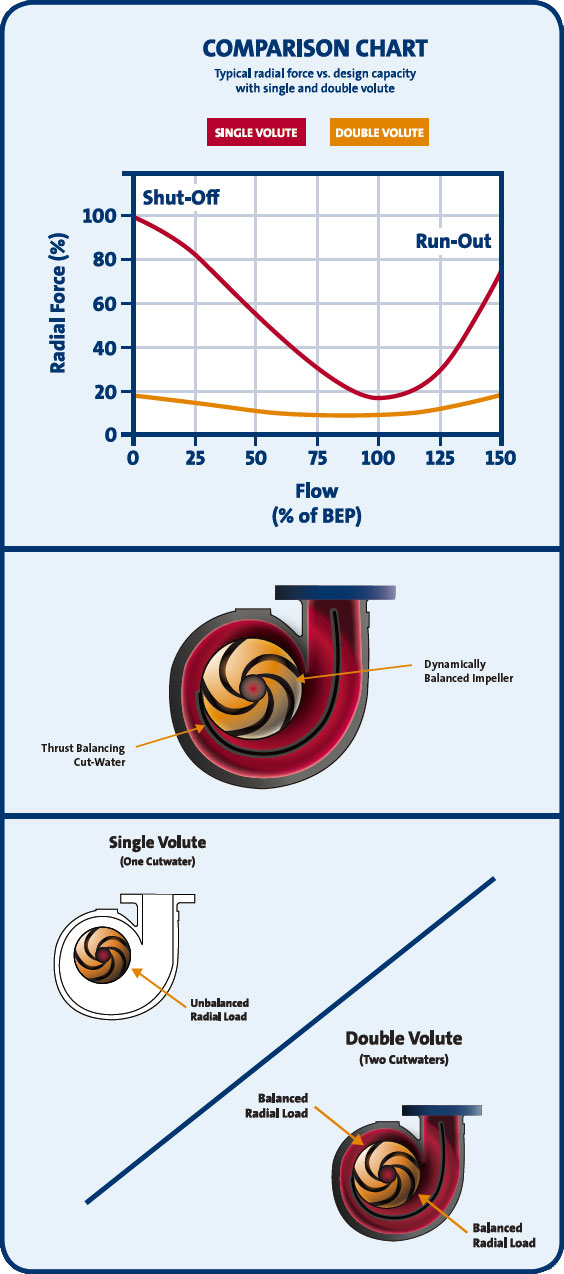

Double Volute Design

Superior Advantages

The PACO L series pumps utilize a double volute design that offers a distinct advantage over single volute designs. The double volute design incorporates two cut waters located at 180 °, which divide the flow into two geometrically similar regions of the volute.

The resultant hydraulic forces within the pumps are equal and opposed. As a result, the net radial force is maintained at a very low level throughout the operating range of the pump, and shaft deflection is kept to a minimum.

A typical single volute pump is normally designed to operate at or near the best efficiency point (BEP).

In actual application, many pumps stray away from BEP due to load variances and/or changes in the system head curve.

As single volute pumps begin to operate away from BEP, the resultant radial load increases dramatically, causing increased shaft loads, deflection, and vibration. Excessive radial loads can cause premature failure of the mechanical seal, bearings, and shaft.

A double volute design ensures that hydraulic radial loads are equal and opposed and thereby nullified.

Pump operation remains stable throughout the entire performance curve, with minimal shaft deflection, prolonging seal, bearing, and shaft life.

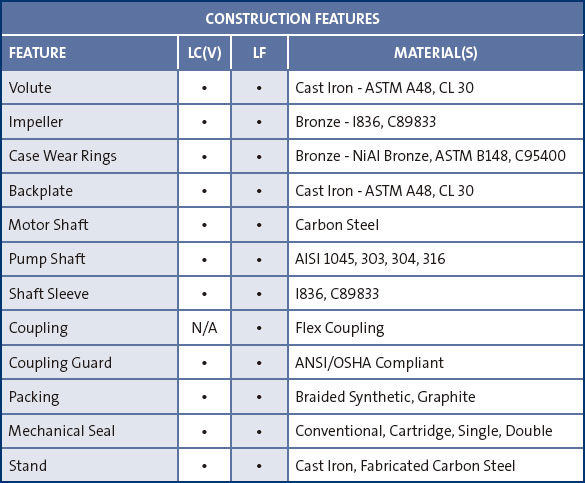

FEATURES AND BENEFITS

| PACO LF FRAME MOUNTED END SUCTION PUMP | |

|---|---|

| Footed Bearing Frame | > Enhances ease of maintenance and provides proper support of rotating equipment during servicing |

| Footless Volute | > Establishes single point support for reducing alignment restrictions, which extend seal and bearing life > Permits discharge orientation flexibility > Minimizes the effects (misalignment, flange strain) of thermal expansion on volute |

| Permanently Sealed for Life Bearings | > Reduce environmental contaminants and pump maintenance |

| Machined Mounting Surfaces and Fabricated Base Plate | > Aid in alignment |

| Choice of Motor Enclosures | > Increases flexibility of design |

| Back Pull-Out Design | > Enables maintenance without disturbing piping |

| Double Volute Design | > Reduces radial loads, internal recirculation, and turbulence, which increases efficiency, lowers life cycle costs, and prolongs seal and bearing life |

| Large Seal Chamber | > Allows for various seal configurations and customization |

| Integrally Cast Diffuser Vane | > Reduces turbulence and pre-rotation by providing laminar flow into oversized impeller eye, resulting in decreased need for extended horizontal suction pipe runs, elbows, or suction guides |

| Francis Vane Impeller Design | > Increases efficiency and reduces NPSHr |

| Bronze Case Wear Rings | > Extend pump life and increase pump efficiency (included as standard) > Provide simple and inexpensive renewal of “like new” operating tolerances, even after years of operation |

| Impellers | > Trimmed to exact customer specifications for customization > Static and dynamically balanced to ISO 1940-G3 for reduced noise and vibration > Hydraulically balanced to decrease thrust loads and prolong seal and bearing life |

THE INDUSTRY STANDARD FOR PREMIUM PUMPS